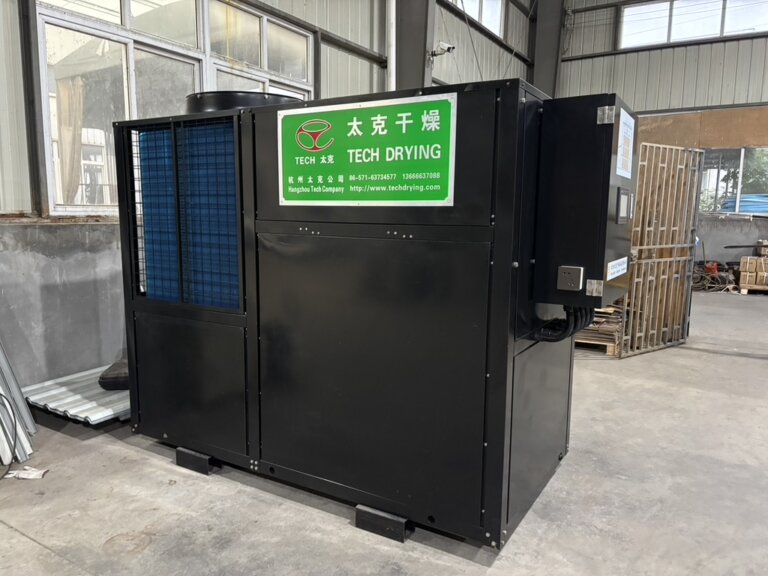

Softwood Fast Drying Kiln

Softwood Fast Drying Kiln

Radiata Pine and More Softwood

3 Times Faster than Conventional Kiln

Built to Last for 20+ Years

Kiln Specification

| Specification | Details |

| Model | KGQ/KGY |

| Capacity | 20-200 m³ |

| Maximum Temperature inside the Kiln | 120 ℃ (248 ℉) |

| Applicable Lumber Types | Radiata Pine and More Softwood |

| Loading Method | Rail and Trolley |

| Kiln Structure Material | Aluminum Alloy |

| Heating Medium | Steam / Hot Water/ Thermal Oil |

| Site Requirements | Indoor / Outdoor |

Key Features

Rapid Drying Performance

Built on conventional designs, this kiln features a high-efficiency reversible fan system that alternates airflow direction to provide uniform moisture distribution across lumber stacks. The system combines enhanced air circulation and improved heating power to dry softwoods 3-5 times faster, while reducing energy consumption through smart control and aerodynamic design.

Drying Technology

With over 25 years of innovation, TECH has perfected species-specific drying protocols for softwoods like pine and spruce, incorporating 6-stage humidity profiling validated through 123,000+ hours of trials across forestry of 23 softwood species.

Robust Construction

It is built to last with a 3003 rust-proof aluminum alloy kiln chamber wall and a 6063 aluminum alloy kiln structure. The base pipes of the heat exchangers and all connection components are crafted from 304 stainless steel. This simplifies maintenance and assembly and also ensures the kiln is free of ferrous metals, corrosion resistance and long-term stability.

Smart Control

The upgraded control system enables precise regulation of temperature and humidity. It enables remote control and real time data management , ensuring user friendly, along with high efficiency and energy conservation.

Softwood Fast Drying Kiln Specification

| Specification | Details |

| Model | KGQ/KGY |

| Capacity | 20 – 200 m³ |

Maximum Temperature Inside the Kiln | 120 ℃ (248 ℉) |

Applicable Lumber Types | Radiata Pine and More Softwood |

| Loading Method | Rail and Trolley |

| Kiln Structure Material | 3003+6063 Aluminum Alloy |

| Heating Medium | Steam / Hot Water / Thermal Oil |

| Site Requirements | Indoor / Outdoor |

Kiln Structure

System Design of Kiln

Air Circulation System

✅ Alluminum and Reversible Fans: All-aluminum, fully reversible fans feature symmetrical impeller blades, ensuring consistent airflow and pressure in both forward and reverse directions. This guarantees uniform moisture content in lumber across the entire airflow path.

✅ Integrated Baffling: Directs airflow through lumber stacks rather than around them, maximizing contact and wood drying efficiency.

✅ High Temperature & Humidity Resistance Motors: Internal motors feature corrosion-resistant casings designed for 100 °C / 100% RH kiln environments.; Optional external motor systems tailored to specific airflow and environmental needs.

Heating System

✅ Robust Material Construction: Base pipes of heat exchanges, in-kiln pipelines, and all connecting parts are crafted from stainless steel, ensuring superior leak resistance and long-term durability.

✅ High-Pressure/Temperature Capability: Equipped with Stellite alloy-sealed electric valves and high-temperature, high-pressure-resistant heat exchangers, the system operates reliably under steam pressure of up to 1.27 MPa.

Smart Control System

✅ Precise Monitoring: Equipped with high-accuracy sensors to monitor temperature/humidity. EMC Test Points: 2; Temperature Test Points: 2; Wood Moisture Content Test Points: 6 – 12

✅ Automatic Control: Define a drying cycle that can contain 10+ stages. Each stage can be customized, including adjustment methods, actuator management, and wood humidity calculation. Pre-configured drying schedules, with the function of storing multiple user–defined programs.

✅ Remote Management: The control system features a touch screen. Also, it enables remote control and real-time data monitoring via mobile/PC devices, significantly reducing manual inspections.

Spray System

✅ Equipped with PPL-sealed electric valves and 304 stainless steel spray pipes, ensuring long-term reliability and corrosion resistance.

Venting System

✅ Equipped with Siemens electric actuators for reliable performance, corression-resistant aluminum alloy louver dampers, and durable silicone seals that maintain airtightness and resist aging.

Kiln Door System

✅ Offers excellent insulation, lightweight design, and strong corrosion resistance. Fitted with silicone sealing strips for reliable, long-lasting airtightness and aging resistance.