Conventional Wood Drying Kiln

- Designed for softwood and hardwood

- Capacity: 10m³ to 200m³

- Heating medium: Steam / Thermal oil / Electricity

- Precise temperature and humidity control. Touch screen and remote access

- Application: Furniture, flooring and most woodworking jobs

Softwood Fast Drying Kiln

- Designed for easy to dry softwood (Radiata Pine)

- Capacity: 10m³ to 200m³

- Maximum drying temperature: 120°C

- Drying speed up to 3-5 times faster than conventional kilns

- Enhanced aerodynamic design and improved heating power

Hardwood High Temperature Kiln

- Designed for thick and dense hardwood (Okoumé, Mahogany)

- Capacity: 2m³ to 20m³

- Drying speed up to 6–8 times faster than conventional kilns

- Heat recovery and air circulation technology

- Durable 304 stainless steel interior

Kiln for Wood Packaging Materials (ISPM15)

- Designed for wood packaging materials like pallets, crates, and dunnage used in international trade

- Meet ISPM-15 and IPPC Standards. Prevent the spread of pests across borders

- Wood Core Temperature Recording

Thermal Modification Kiln

- 160 - 250 °C (320 - 482 ℉) Heat Treatment in a low-oxygen environment

- Boast dimensional stability, decay and weather resistance. Obtain appealing, uniform color on the wood

- Application: Suitable for geothermal floors and outdoor use (siding, decks, fences)

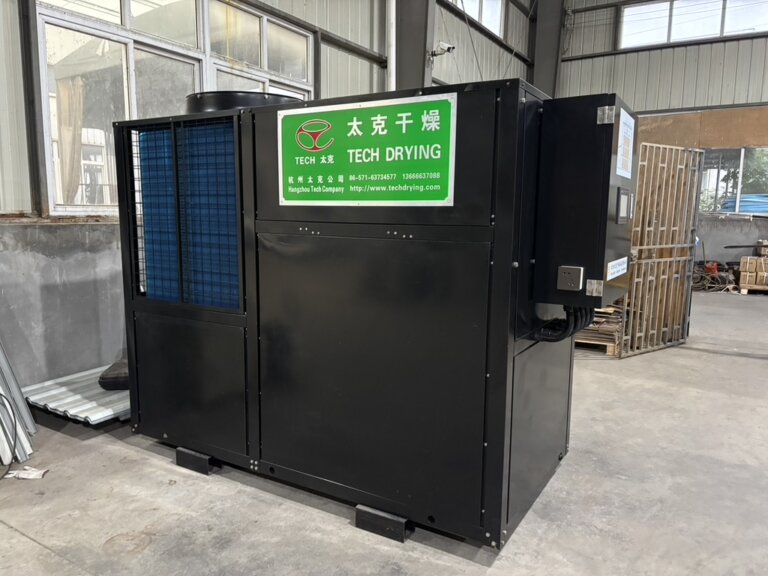

Dehumidification Wood Kiln

- Designed for High-Value Wood, Delicate Wood, Secondary Drying or Wood Product Treatment

- Operate at drying temp 27°C – 49°C and heat treating 49°C – 70°C

- Saves up to 75% energy

- Precise drying, ensuring consistent and high-quality wood drying

Training & Technical Support

- Hands-on Kiln Operation Workshops: Step-by-step guidance on temperature/humidity system calibration for different wood species (hardwood/softwood)

- 24/7 Remote Diagnostics: Real-time IoT monitoring of kiln control systems Quick troubleshooting for electrical, heating, and ventilation issues

- Technical support by professors, experienced engineers and certified technicians

Kiln Accessories

- TECH PLC , LiTOUCH, Hozmeister M800B (Delphi) Control System

- Siemens Electric Damper Actuator for Venting System

- Fan System (Aluminum Alloy Fan, High Temperature Resistant Motor)

- Heat Exchanger (Stainless Steel Base)

- Electric Valve for Heating System

- Solenoid Valve for Spraying System

Drying Kilns Built for Your Lumber Business

Made in China, Trusted Globally – With over 3,000 wood kilns in operation worldwide, including customers from 46 countries across Europe, Africa, South & Central America, Oceania, and Asia.

Boost Your Lumber Business – High-quality wood kiln dryer perfect for sawmills, furniture factories, flooring producers, and timber exporters. We can help you scale up your kiln dryer capacity with our innovative kiln drying solutions.

Frequently Asked Questions

What wood species can your wood drying kilns process?

Our wood kilns can handle a wide range of hardwoods and softwoods, including mahogany, Okoume, Oak, pine and more. Whether you need a conventional kiln or a hardwood kiln for specialty woods, we offer versatile solutions for most wood species.

What is the drying capacity of your kilns?

Our conventional kilns are available in single – unit volume ranges from 10 to 200 cubic meters (4000-80000 board feet). We can also customize the kilns to meet your specific needs. In the past, we’ve delivered 112 kilns to clients in one go.

How much does a wood kiln for sale?

The price of a drying kiln for sale varies depending on size, capacity, and features. We offer scalable options from small wood kilns to large industrial units. Contact our experts for a customized quote suited to your wood drying kiln needs.

How does a wood drying kiln improve wood quality?

By precisely controlling heat, airflow, and humidity, our wood drying kilns prevent defects like cracking, warping, and fungal growth. This results in stronger, dimensionally stable timber with a superior surface finish, ideal for high-value markets and international exports.

Are your kilns energy-efficient and environmentally friendly?

Absolutely. Our wood drying kilns incorporate energy-saving technologies like heat recovery systems and thermal break technology. These features reduce operational costs and minimize carbon footprint — an important lumber businesses.

Can I monitor and control the kiln remotely?

Yes. Our kilns feature smart control systems allowing real-time monitoring and remote management of temperature, humidity, and drying cycles. This advanced control improves convenience and ensures consistent timber drying quality — no matter where you operate.

How long does it take to manufacture the kiln?

Depending on the model, manufacturing usually takes 2–8 weeks, followed by 4–8 weeks for delivery based on your location.

We strictly follow ISO 9001 standards and implement rigorous quality control at every stage to ensure your kiln is delivered on time, with performance you can trust.

Do you offer installation and training support?

Yes, we provide full installation, commissioning, and operator training for our wood kilns for sale. Our onsite training support ensures you maximize kiln performance, maintain equipment properly, and achieve consistent wood drying results.