Hardwood High Temperature Kiln

Hardwood High Temperature Kiln

Dense and Thick Hardwood

Heat Recovery & Thermal Break Tech

6-8 Times Faster than Conventional Kiln

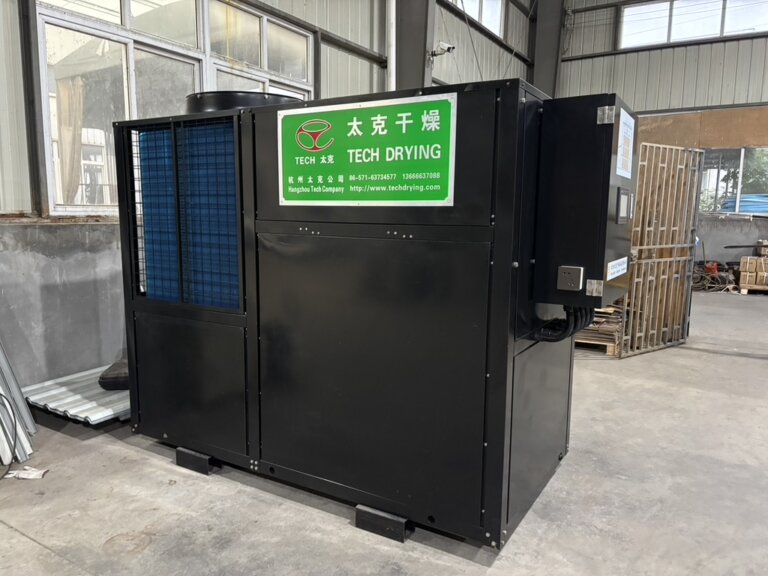

Hardwood High Temperature Kiln Specification

| Specification | Details |

| Model | GWD/GWY/GWQ |

| Capacity | 2 – 20m³ |

Maximum Temperature Inside the Kiln | 150 ℃ (302°F) |

Applicable Lumber Types | Hardwood |

| Loading Method | Rail and Trolley |

| Kiln Structure Material | 304 Stainless Steel Interior |

| Heating Medium | Steam / Thermal Oil / Electricity |

| Site Requirements | Indoor / Under Shelters |

Heat Recovery Technology

Features of Hardwood High Temperature Kiln

Air Circulation Technology

✅ External motor with the unique design of the fan shaft structure and bearing lubrication enables the fans to be positioned anywhere within the kiln as required. This allows for precise regulation of the air dynamic circulation, ensuring a uniform heat flow distribution. Consequently, the drying uniformity and efficiency of the lumber are enhanced.

Thermal Break Technology

✅ With a 150–200mm high-performance insulation layer and advanced thermal break technology, the system effectively minimizes heat loss by interrupting heat conduction paths through the kiln structure.

Construction for Enhanced Durability

✅ The interior of the kiln is made of 304 stainless steel, offering excellent corrosion resistance and a long service life.